Flake Sorter

The Lindner Flake Sorter is an advanced classification system for plastic flakes, designed to refine material quality after washing and drying processes. By integrating controlled air separation, density distinction and aerodynamic response sorting, the system reliably differentiates light, heavy and fine contaminants, delivering higher-quality output ready for downstream extrusion, pelletizing or compounding.

Xpert

The Lindner Xpert De-Labeller is a specialized label removal system engineered to reliably separate labels, sleeves and coating films from plastic packaging, without shredding or damaging the base plastic material. This preserves material quality for downstream washing, sorting and granulation processes in advanced recycling lines.

Komet

The Lindner Komet is a precision secondary single-shaft shredder engineered to further reduce and refine the particle size of pre-shredded materials in industrial recycling lines. With its robust construction, internal feeding system, and efficient drive, the Komet delivers stable 24/7 operation with superior particle quality and minimal downtime.

Universo

The Lindner Universo is a universal single-shaft shredder engineered to handle a wide range of materials in recycling and waste processing applications. From post-consumer plastic bales to complex industrial waste, Universo delivers robust performance, versatility and high throughput even under demanding operating conditions.

Jupiter

The Lindner Jupiter is a heavy-duty single-shaft primary shredder designed for the first stage of processing plastics and industrial waste. Its trusted shredding technology delivers continuous operation 24/7, high energy efficiency, and consistent output particle size — ideal for downstream sorting and washing processes.

Micromat Serie IV

The Lindner Micromat Series IV is a reference solution in the field of industrial shredding for waste and recycling applications. Designed to process heterogeneous materials with consistent output quality, this single-shaft shredder is widely used in plants focused on SRF/RDF production, plastics recycling, wood waste processing and industrial waste treatment.

Thanks to its robust construction, high-inertia rotor and precise cutting system, the Micromat IV ensures reliable size reduction and controlled particle size, supporting efficient downstream separation and recovery processes. The machine is particularly suited for facilities seeking operational continuity, reduced downtime and optimized energy consumption.

Integrated by Cesaro Mac Import into complete recycling lines, the Micromat Series IV becomes part of engineered solutions tailored to the characteristics of the input material and the final application, contributing to higher process efficiency and increased value of recovered materials.

Urraco 95 evo

The Lindner Urraco Evo 95 is engineered for processing heavy scrap and metal waste in industrial environments where high torque, structural strength and the ability to handle intensive loads are essential.

Its low-speed twin-shaft configuration ensures reliable primary shredding, with controlled processing and machine protection even under severe operating conditions. Within plant systems integrated by Cesaro Mac Import, the Evo 95 is a strategic solution for metal recycling facilities focused on productivity, durability and continuous operation.

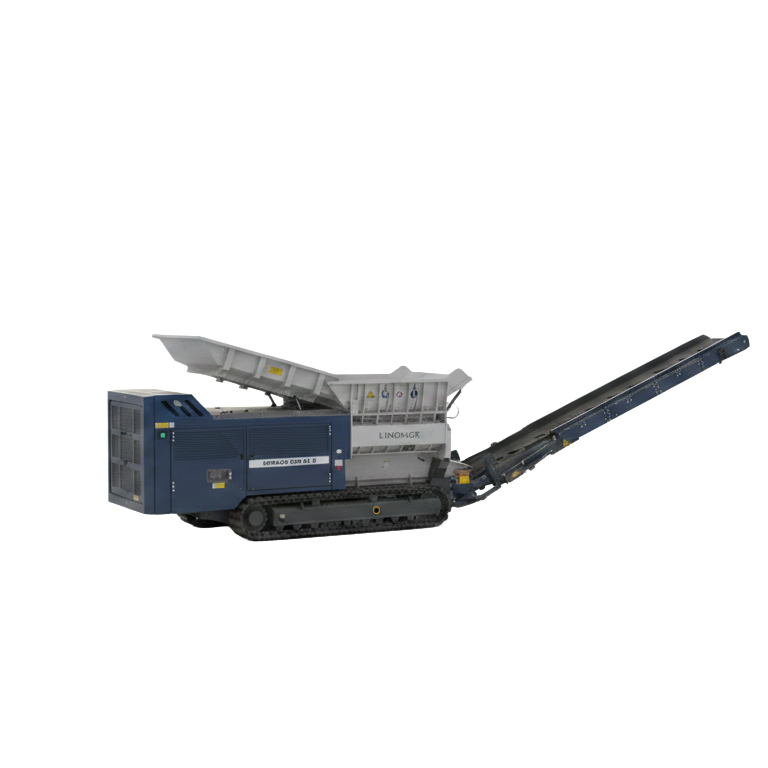

Urraco 85 evo

The Lindner Urraco Evo 85 is a reference solution for primary shredding of scrap and metal waste in high-demand industrial environments. Designed to deliver the right balance between power, structural strength and operational continuity, it ensures stable performance even with variable material flows.

Its twin-shaft technology effectively manages mechanical stress, protecting the machine and improving overall plant reliability. Integrated into plant solutions engineered by Cesaro Mac Import, the Evo 85 supports efficient volume reduction and optimal scrap preparation for metal recovery processes.

Urraco 75 evo

The Lindner Urraco Evo 75 is a twin-shaft primary shredder designed for industrial applications focused on scrap and metal waste processing. Thanks to its low-speed, high-torque technology, the machine ensures controlled shredding with reduced vibrations and limited wear, even when handling heterogeneous materials.

Used in metal recovery plants and scrap processing lines, the Evo 75 provides efficient volume reduction, preparing materials for downstream separation and recovery stages. Integrated by Cesaro Mac Import into complete plant solutions, it is a reliable choice for ensuring operational continuity and process stability.

360 G

Description: The SENNEBOGEN 360 G is a robust multifunction machine engineered to handle demanding operations across industrial, forestry, and agricultural sectors. Featuring a 360° rotating uppercarriage, it combines the capabilities of an excavator, telehandler, and crane—delivering exceptional flexibility and power in a single, compact solution. Built for superior stability and load capacity on rough terrain, […]

Merak 2800

Merak 2800 is the new star of the Lindner range, designed to set new standards in shredding through an unprecedented combination of versatility, efficiency and productivity. Distinctive features: Main applications: Available cutting systems:

Methor

Our multi-tool Methor offers the widest variety of applications of its class. The shredding of industrial waste, construction and demolition waste, mattrasses, building rubble, biowaste or waste wood, for example, do not pose a problem, but even entangled waste from paper and plastic production, the shredding of rolls or roll goods or magnetic tape scrap […]

Inventhor Type 6.2

THE INVENTHOR 6.2 SETS SHREDDING EFFICIENCY STANDARDS Benefit from its unique VarioDirect Drive, highest uptime and simple, flexible operation, right from the first ton. Get to know the successor of the DW 3060 and take advantage of the latest Doppstadt shredder generation for your business! OUTSTANDING EFFICIENCY The new Inventhor 6.2 stands for more efficiency, […]

CERON Type 308 Stationary

The CERON TYPE 308 is the perfect combination of high quality technology, high efficiency and long service life. The machine frame and the drive system have been dimensioned to suit the highest requirements and work loads without making any compromises. SPECIALS The CERON TYPE 308 is the largest machine in our CERON family. With the […]

CERON Type 256 Stationary

The CERON TYPE 256 provides maximum flexibility for all typical pre-shredding tasks thanks to its powerful drive system and wear-resistant roller and comb teeth as well as diverse equipment variations. SPECIALS The CERON TYPE 256 operates utilizing the low-speed principle: The roller, which is 2.5 m long and 0.6-0.8 m thick, tears the incoming material continuously through […]

CERON Type 206 Stationary

The low-speed CERON TYPE 206 shredder demonstrates its effectiveness especially when it comes to difficult shredding tasks and offers the opportunity to handle a large number of recycling tasks – while ensuring the highest level of tolerance to obstructions. SPECIALS The roller of the CERON TYPE 206, which is 2 m long and 0.6 m thick, uses […]

Inventhor Type 9

The INVENTHOR TYPE 9 opens up completely new possibilities when it comes to effective shredding: From material feed to product removal, it stands out thanks to a whole number of innovations – for instance, the new VarioDirect Drive, which continuously transmits power to the shredding drum so that the engine always runs at the optimum […]

CERON Type 306 Stationary

The CERON TYPE 306 is distinguished by its power and performance when handling extremely difficult shredding jobs and can be ideally adapted to every process thanks to its wide variety of equipment options. SPECIALS The roller, which is 3 m long and 0.6 m thick, is equipped with 21 teeth, ensuring that the CERON TYPE 306 reliably […]