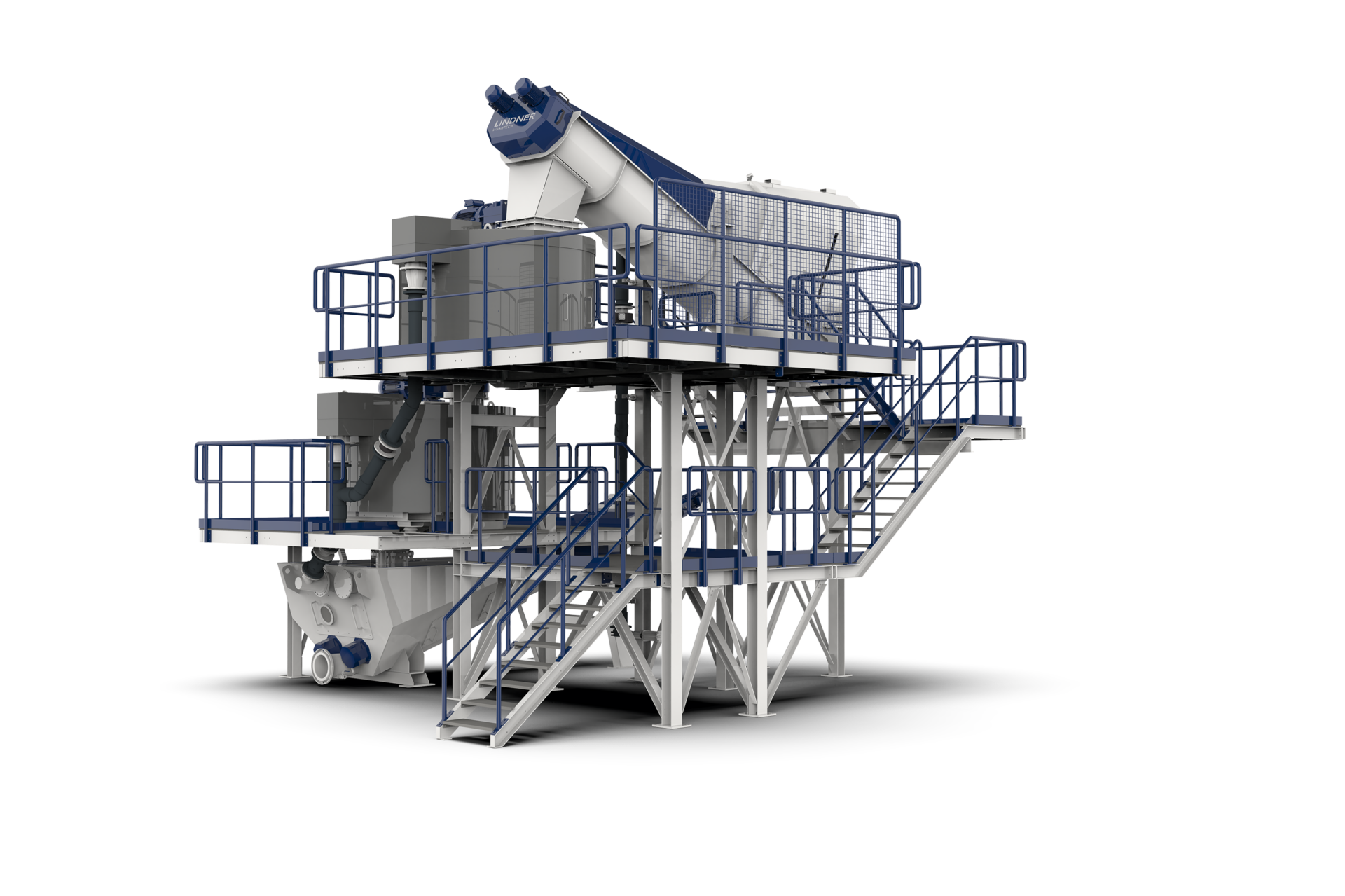

Advanced Thermal Washing Solution

The Lindner Hot-Wash System is an advanced thermal washing solution designed for the removal of persistent contaminants from plastic materials. Engineered for demanding recycling applications, it effectively eliminates oils, greases, adhesives, labels, food residues and odors, significantly improving the quality of the recycled output.

By combining thermal treatment, chemical dosing and mechanical agitation, the Hot-Wash System delivers continuous and controlled cleaning performance for heavily contaminated plastic streams.

Key Features

- High-temperature washing process, enhancing the removal of stubborn organic and adhesive contaminants.

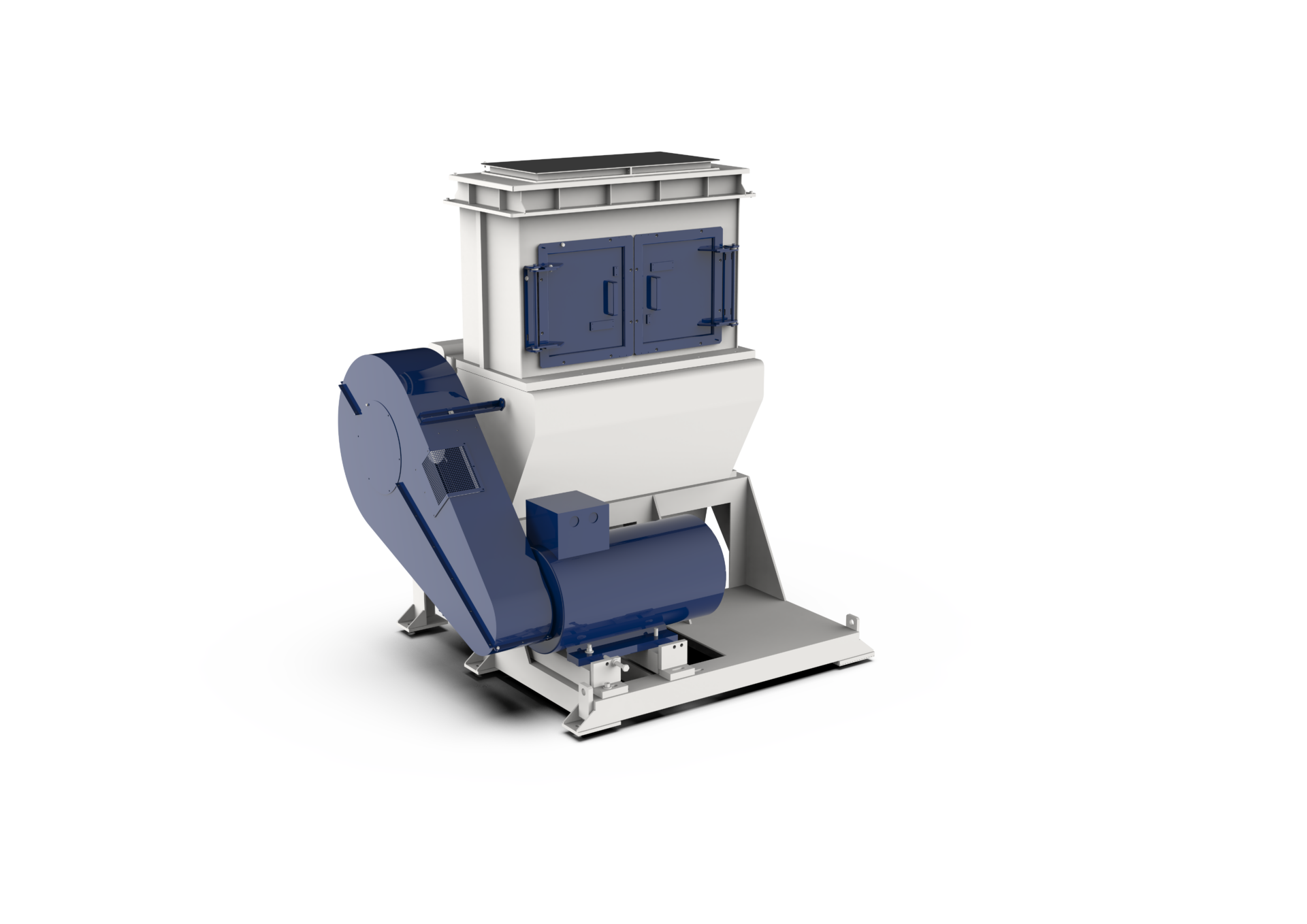

- Integrated reactor system, ensuring controlled retention time and uniform material treatment.

- Combination of mechanical and chemical cleaning, for maximum washing efficiency.

- Process parameter control, including temperature, dosing and circulation management.

- Heavy-duty construction, designed for continuous industrial operation.

Operational Advantages

- Significant improvement in material purity, essential for high-quality recyclate production.

- Effective removal of odors and organic residues, particularly important for post-consumer plastics.

- Enhanced downstream performance, as cleaner material improves separation, drying and extrusion stages.

- Stable and repeatable process, ensuring consistent output quality.

Why the Hot-Wash System is Strategic in Plastic Recycling Lines

The Hot-Wash System represents the critical deep-cleaning stage in advanced plastic washing plants. By targeting contaminants that cannot be removed through mechanical washing alone, it elevates the overall quality level of the recyclate. This directly impacts the performance of subsequent processing steps and enables the production of higher-value recycled materials suitable for more demanding applications.