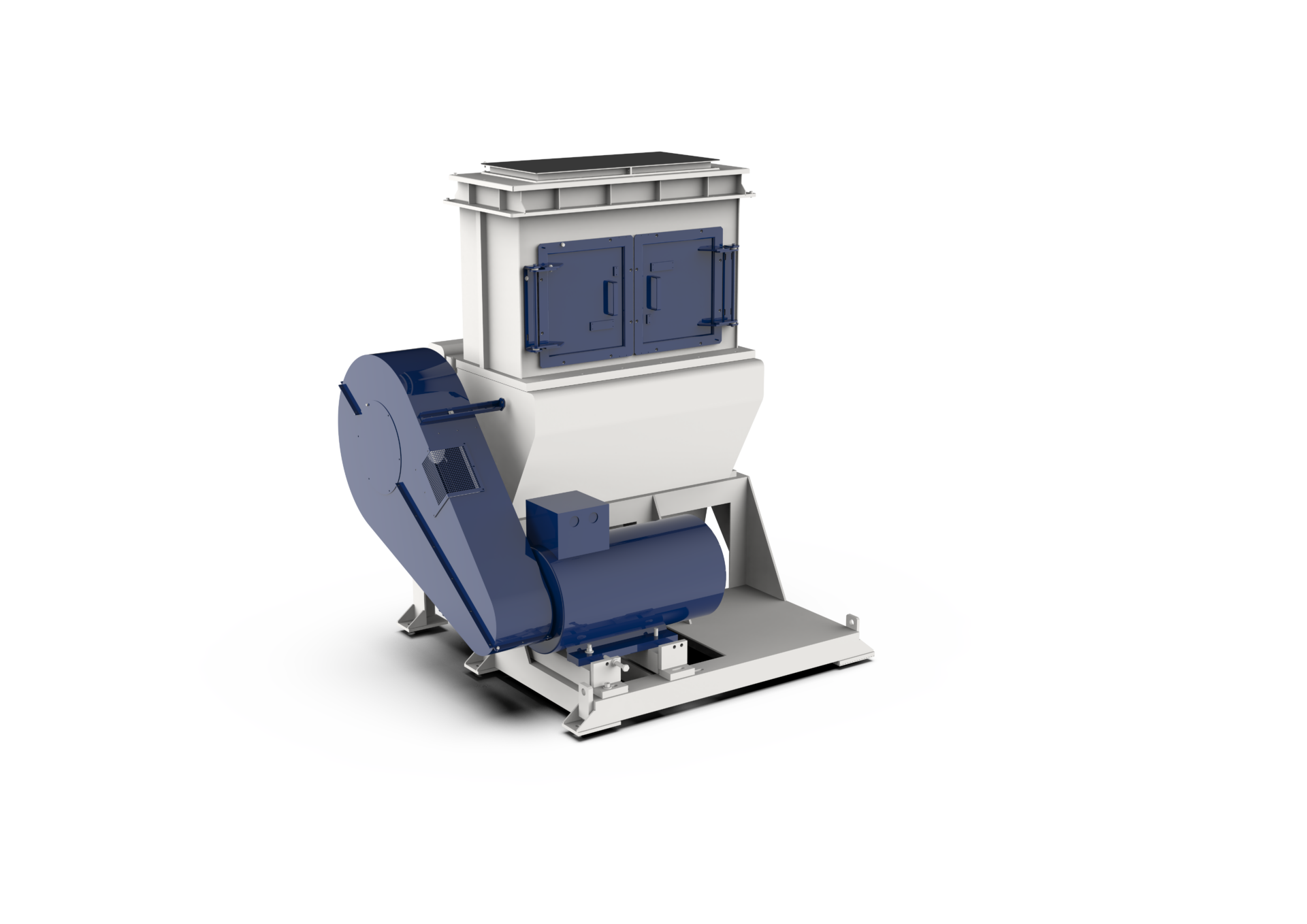

High-Performance Wet Size Reduction System

The Lindner Wet Granulator is a high-efficiency size reduction unit designed to operate under wet conditions within plastic washing lines. It performs precise granulation of plastic materials while simultaneously supporting the washing process, ensuring optimal particle size for downstream separation and drying stages.

By combining mechanical cutting with water-assisted processing, the Wet Granulator improves both material preparation and cleaning efficiency.

Key Features

- Wet granulation process, enabling simultaneous size reduction and pre-cleaning.

- Precision cutting system, delivering uniform flake size for improved downstream performance.

- Water-assisted operation, helping to remove dirt and prevent heat buildup during processing.

- Robust industrial construction, designed for abrasive and contaminated materials.

- Seamless integration, compatible with complete plastic washing lines.

Operational Advantages

- Consistent particle size, enhancing separation, washing and drying efficiency.

- Reduced thermal stress on material, preserving polymer quality.

- Improved contaminant removal, as water flow supports cleaning during cutting.

- Stable continuous operation, even with heavily contaminated input streams.

Why Wet Granulator is Strategic in Plastic Recycling LinesThe Wet Granulator plays a crucial role in preparing plastic materials for effective washing and separation. By ensuring uniform granulation while assisting in contaminant removal, it stabilizes the process flow and increases overall plant efficiency. This leads to higher recyclate quality, better process performance and reduced operational costs.