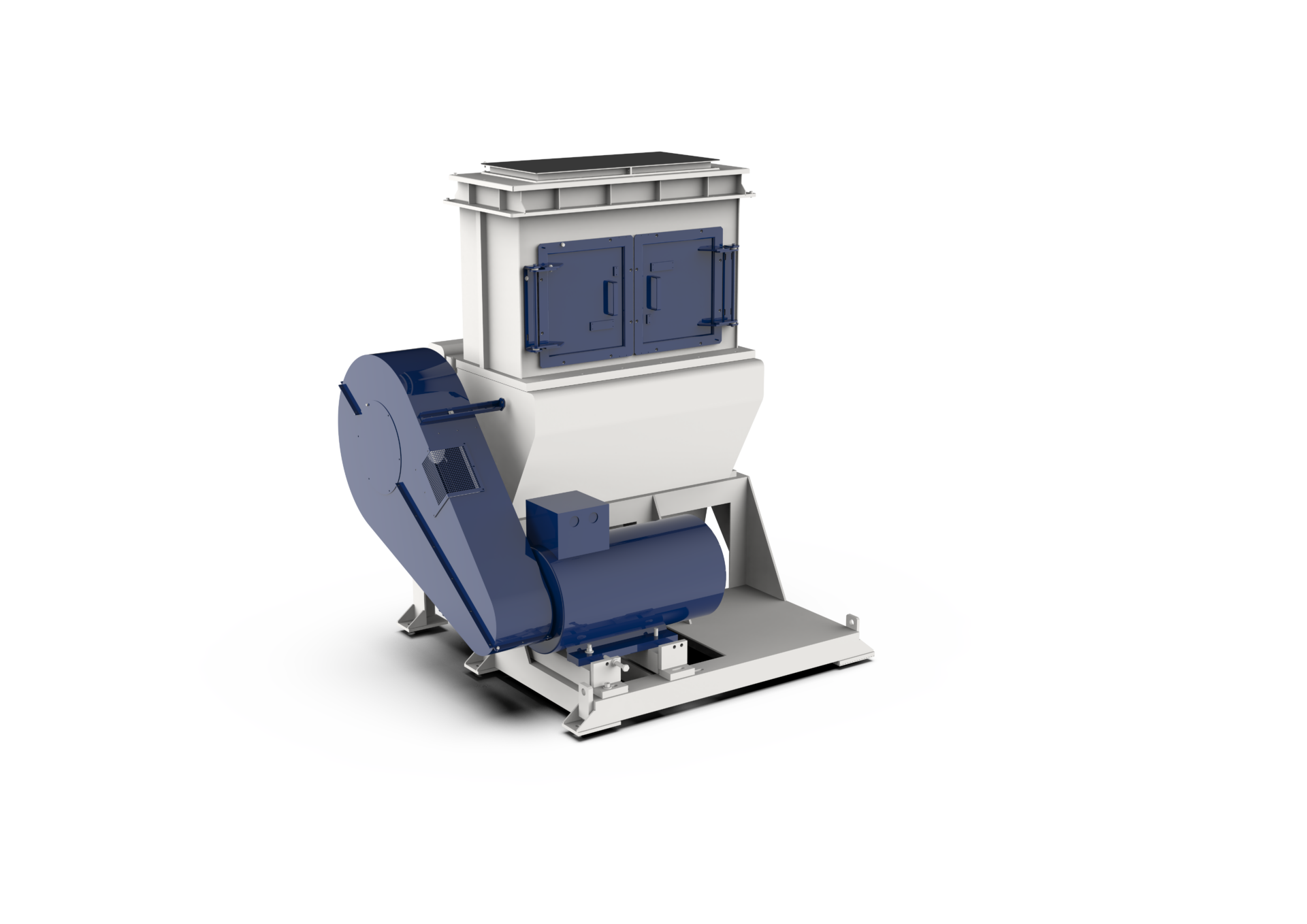

High-Efficiency Centrifugal Drying System

The Lindner Loop Dryer is a high-efficiency mechanical drying unit designed to remove residual moisture from plastic fractions after the washing stages. Integrated into advanced recycling lines, it delivers dry and clean material, ready for subsequent separation, refinement or extrusion processes.

Using the principle of controlled centrifugal force, the Loop Dryer ensures effective dewatering with minimal material loss and continuous process stability.

Key Features

- High-speed centrifugal drying, enabling efficient removal of surface water.

- Different rotor diameter configurations, adaptable to various throughput capacities and material types.

- Automatic cleaning system, maintaining consistent performance over time.

- Wear-resistant stainless-steel construction, ideal for wet and abrasive environments.

- Continuous operation design, ensuring seamless integration into plastic washing lines.

Operational Advantages

- Significant reduction of residual moisture, improving the efficiency of final drying or extrusion stages.

- Low material loss, thanks to controlled mechanical treatment.

- Stable and consistent material flow, supporting reliable process performance.

- Reduced overall energy consumption, as it lowers the load on downstream thermal drying systems.

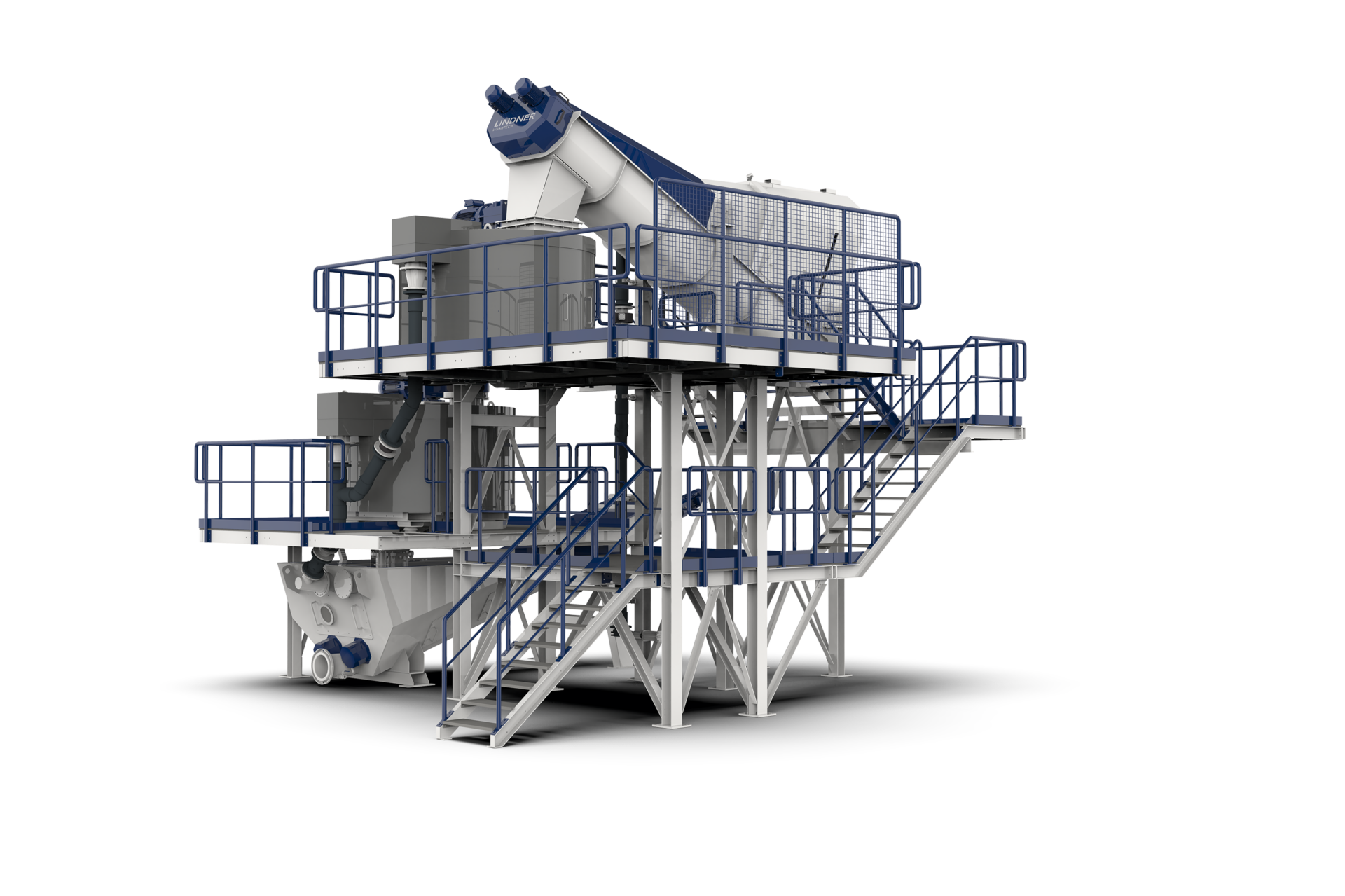

Why Loop Dryer is Strategic in Plastic Washing LinesThe Loop Dryer represents the key mechanical dewatering stage in plastic recycling systems. By rapidly removing residual water after washing, it stabilizes the material and enhances the performance of downstream drying units. This leads to higher plant efficiency, improved recyclate quality and lower operating costs.