SAerodynamic Separation System

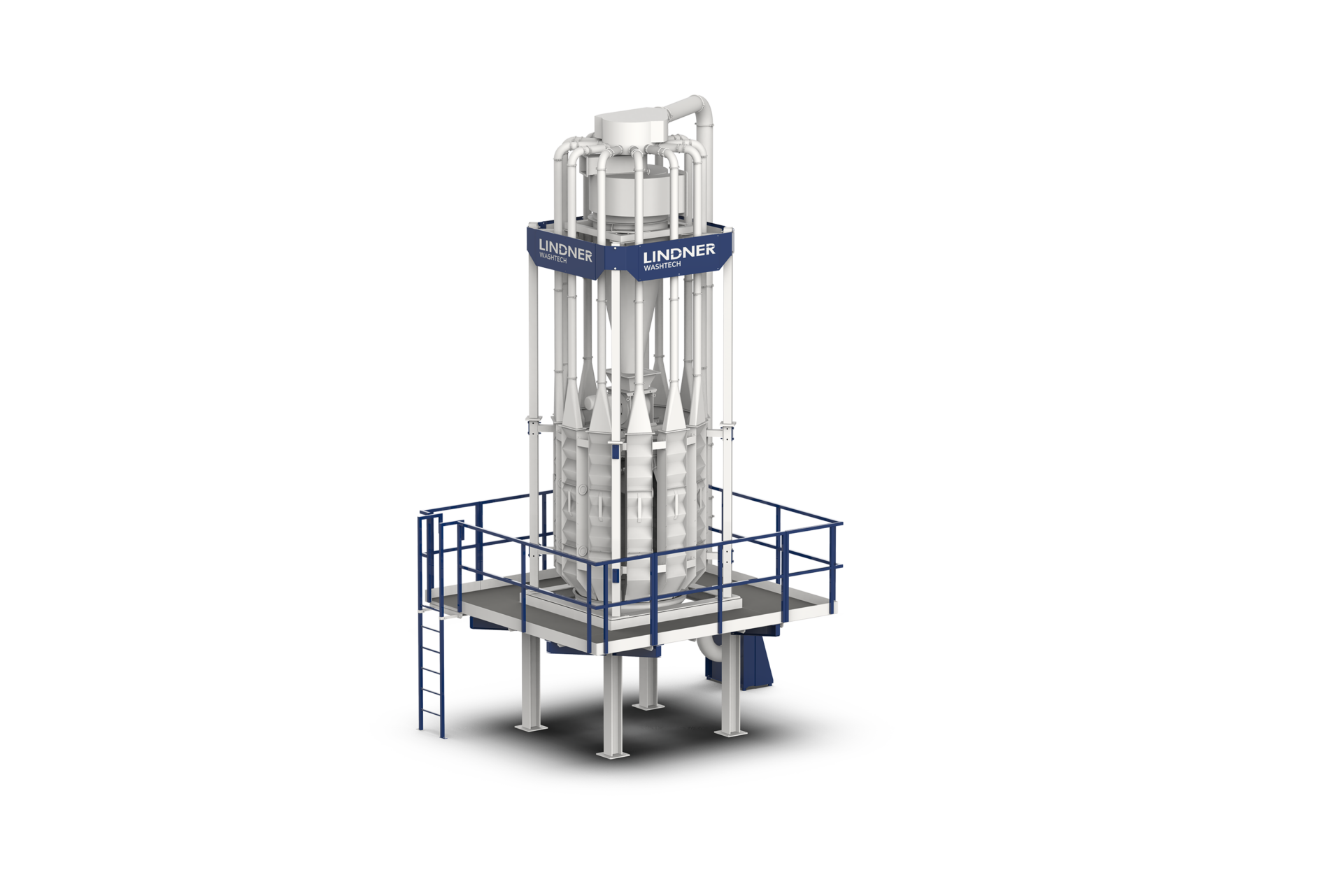

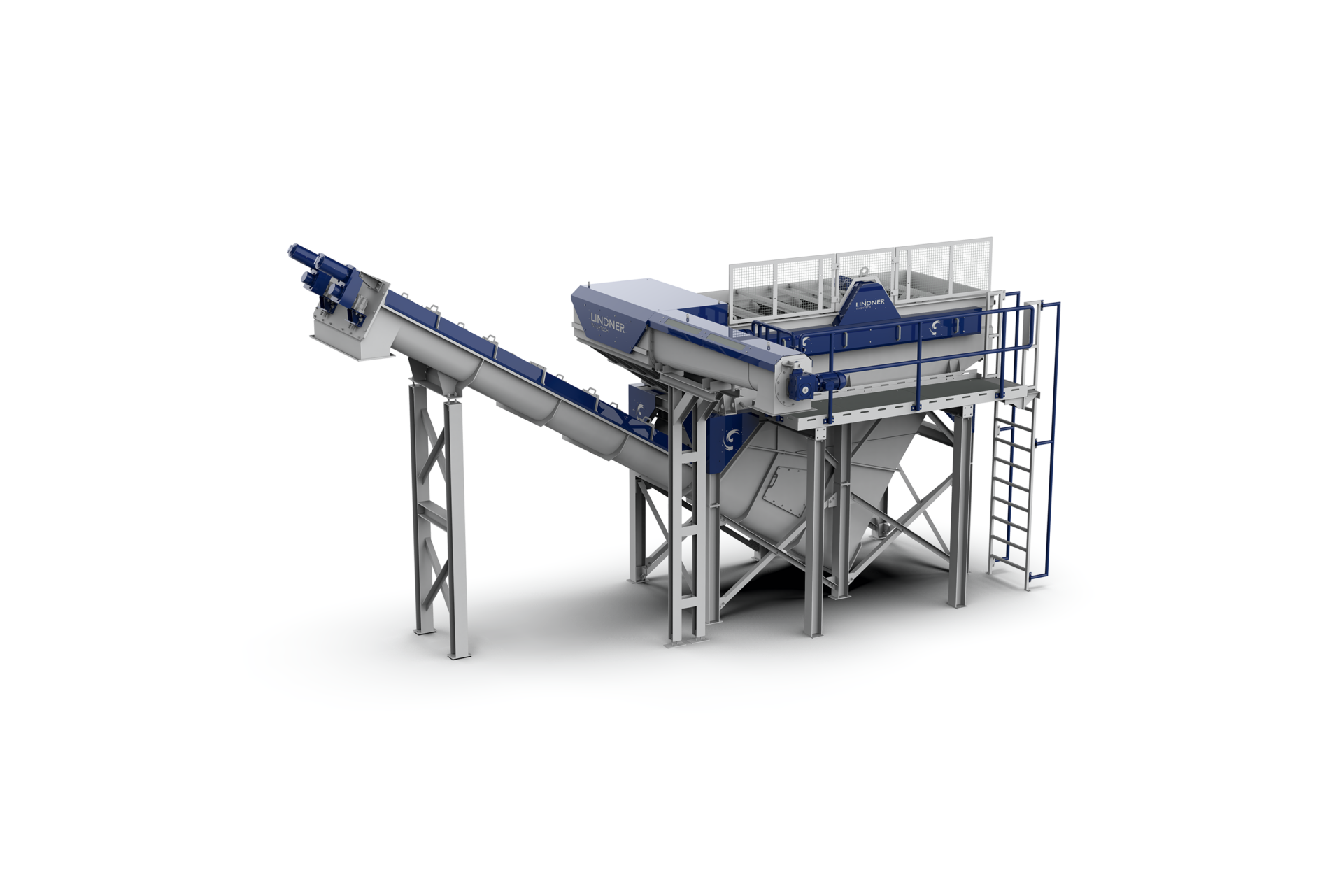

The Lindner Cascade Wind Sifter is a high-precision air separation system designed to divide light and heavy materials based on their aerodynamic properties. Integrated into recycling and processing lines, it enables the effective removal of unwanted light fractions, improving the quality of material directed to downstream processes.

Using a controlled cascading airflow principle, the system ensures stable and adjustable separation performance, even when handling heterogeneous material streams.

Key Features

- Cascading aerodynamic separation, providing precise differentiation between light and heavy fractions.

- Adjustable airflow parameters, adaptable to different material types and process requirements.

- High efficiency in removing light contaminants, such as thin films, paper and other unwanted light materials.

- Robust industrial construction, designed for continuous operation.

- Modular integration, easily incorporated into new or existing processing lines.

Operational Advantages

- Improved output material quality, reducing the presence of unsuitable light fractions.

- Higher efficiency of downstream processes, including fine shredding, washing and density separation.

- Stable and controllable process performance, even with variable input streams.

- Reduced rejects and higher recovery rates, thanks to more accurate separation.

Why Cascade Wind Sifter is Strategic in Recycling LinesThe Cascade Wind Sifter represents a key refinement stage in recycling systems. By effectively removing unwanted light materials, it stabilizes feedstock quality and enhances the performance of downstream equipment. This leads to higher product purity, improved process efficiency and greater value of the recovered material.