Optical Sorting System for Plastic Flakes

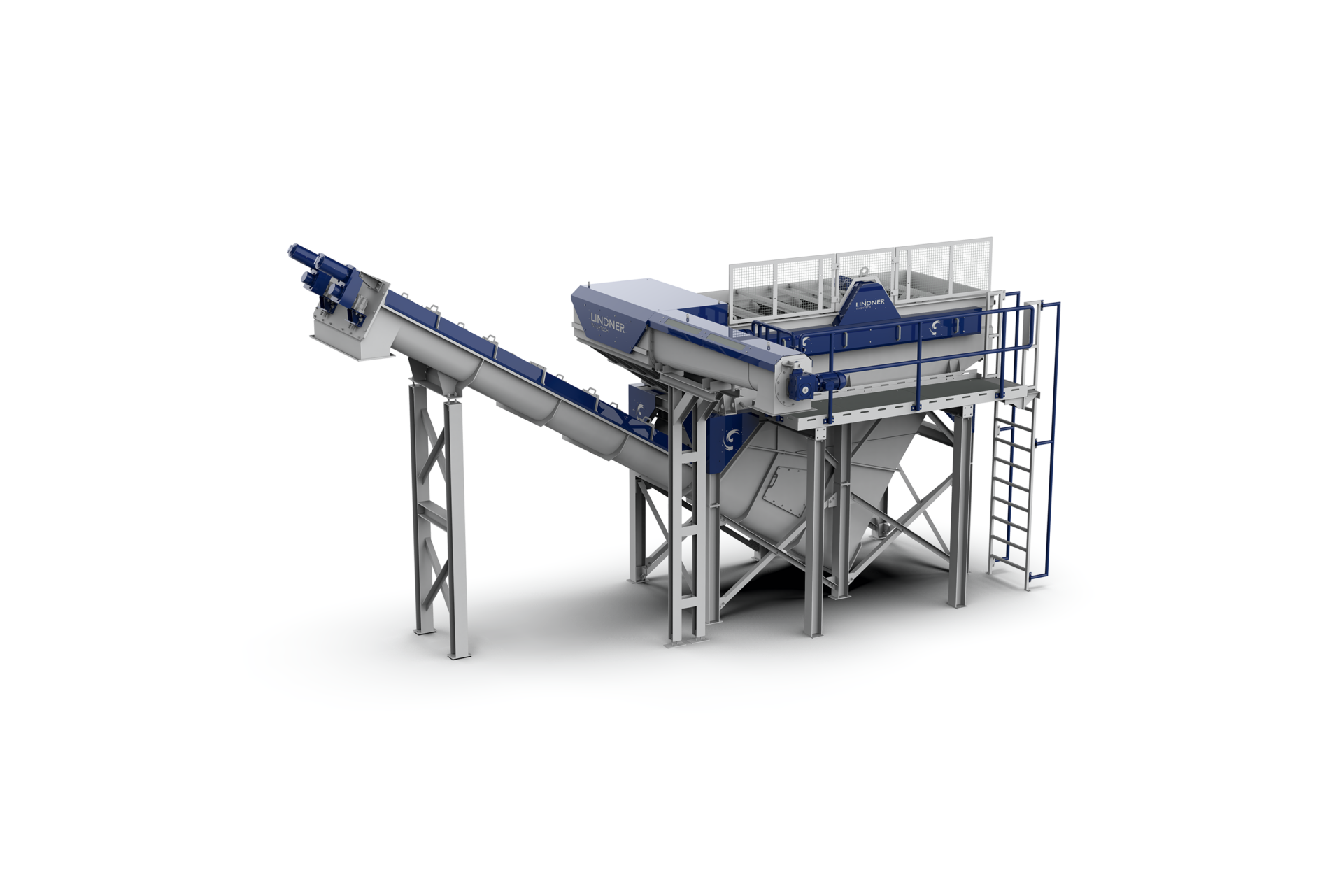

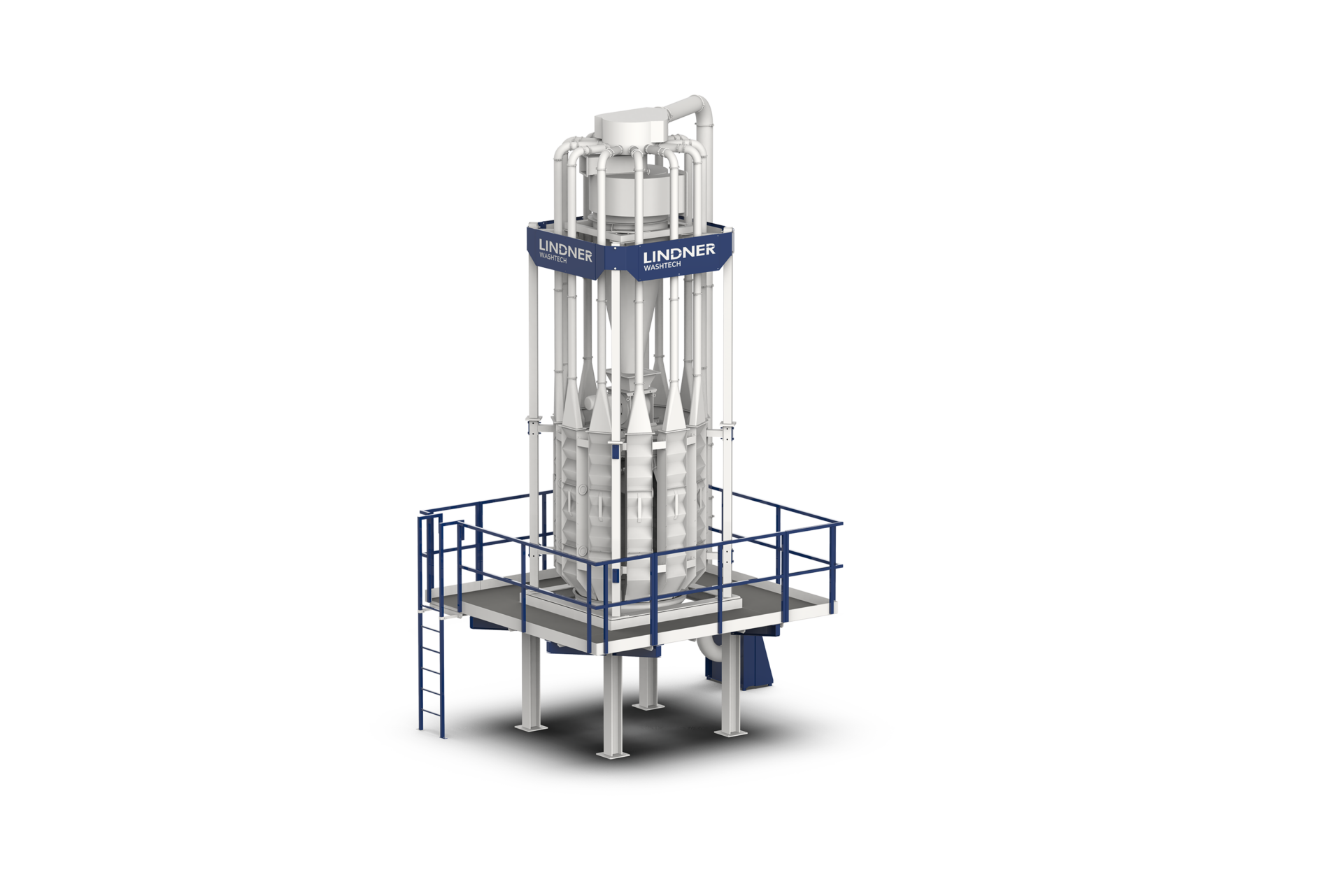

The Lindner Flake Sorter is a high-precision optical sorting system designed for the separation and purification of plastic flakes after shredding and washing stages. Integrated into advanced recycling lines, it removes contaminants and unwanted polymers, ensuring a high-quality recycled output.

Using advanced detection technologies combined with fast and accurate ejection systems, the Flake Sorter significantly improves the purity of the output fractions.

Key Features

- High-resolution optical detection technology, enabling accurate identification of polymers and contaminants.

- High-speed air ejection system, ensuring precise removal of unwanted flakes.

- Suitable for various plastic types, including PET, PE, PP and mixed fractions.

- Modular configurations, adaptable to different throughput capacities and plant requirements.

- Inline integration, fully compatible with washing and refining lines.

Operational Advantages

- Increased recyclate purity, enhancing the value of the final product.

- Greater stability in extrusion processes, thanks to consistent flake quality.

- Reduced rejects, improving recovery of usable material.

- Continuous quality control, directly within the production flow.

Why Flake Sorter is Strategic in Recycling LinesThe Flake Sorter represents a key refinement stage in plastic recycling systems. By removing optical contaminants, wrong polymers and unwanted fractions, it enables the production of premium-quality recyclates with stable characteristics. This results in higher product value, improved process reliability and stronger market competitiveness.