Inline Quality Optimization System

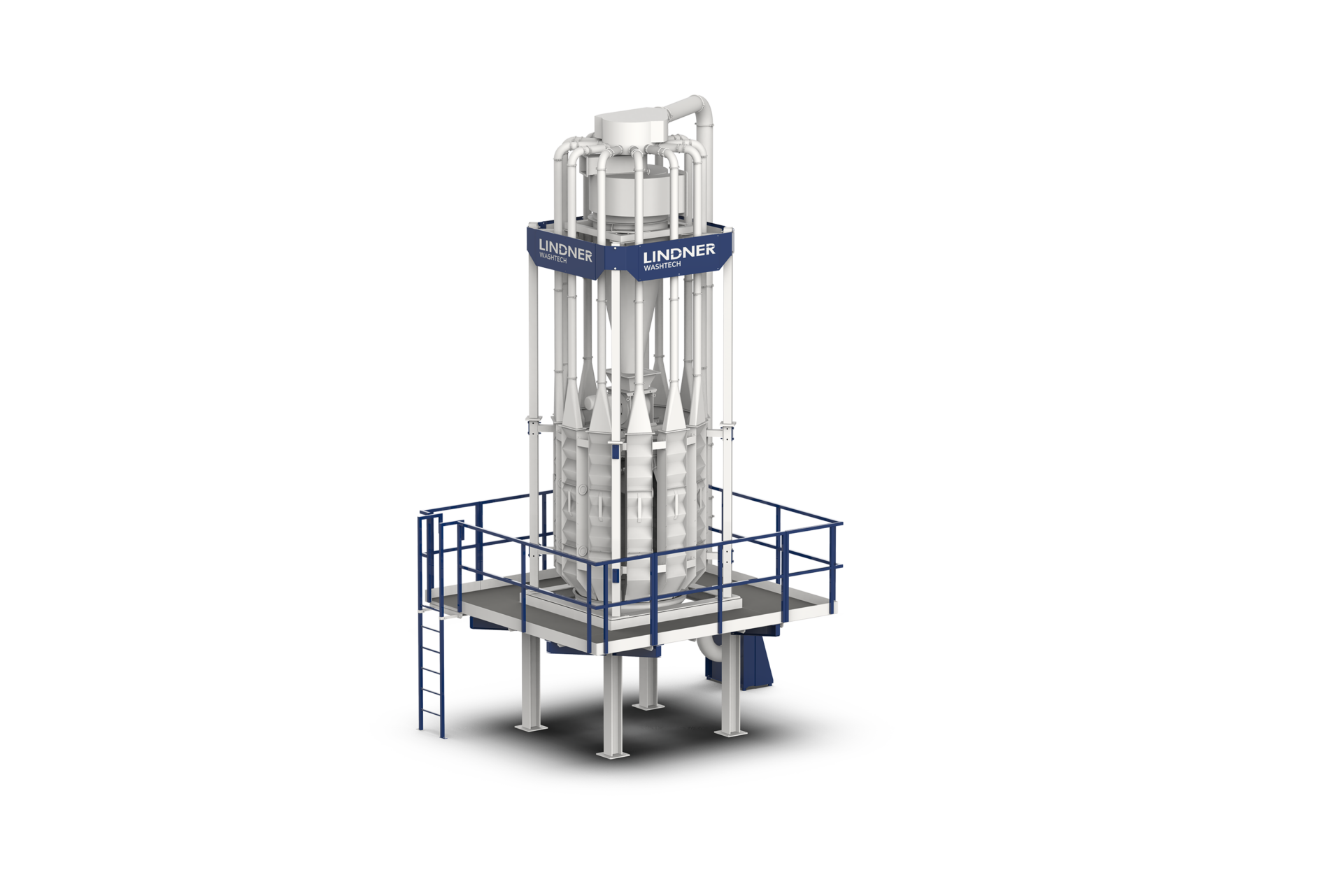

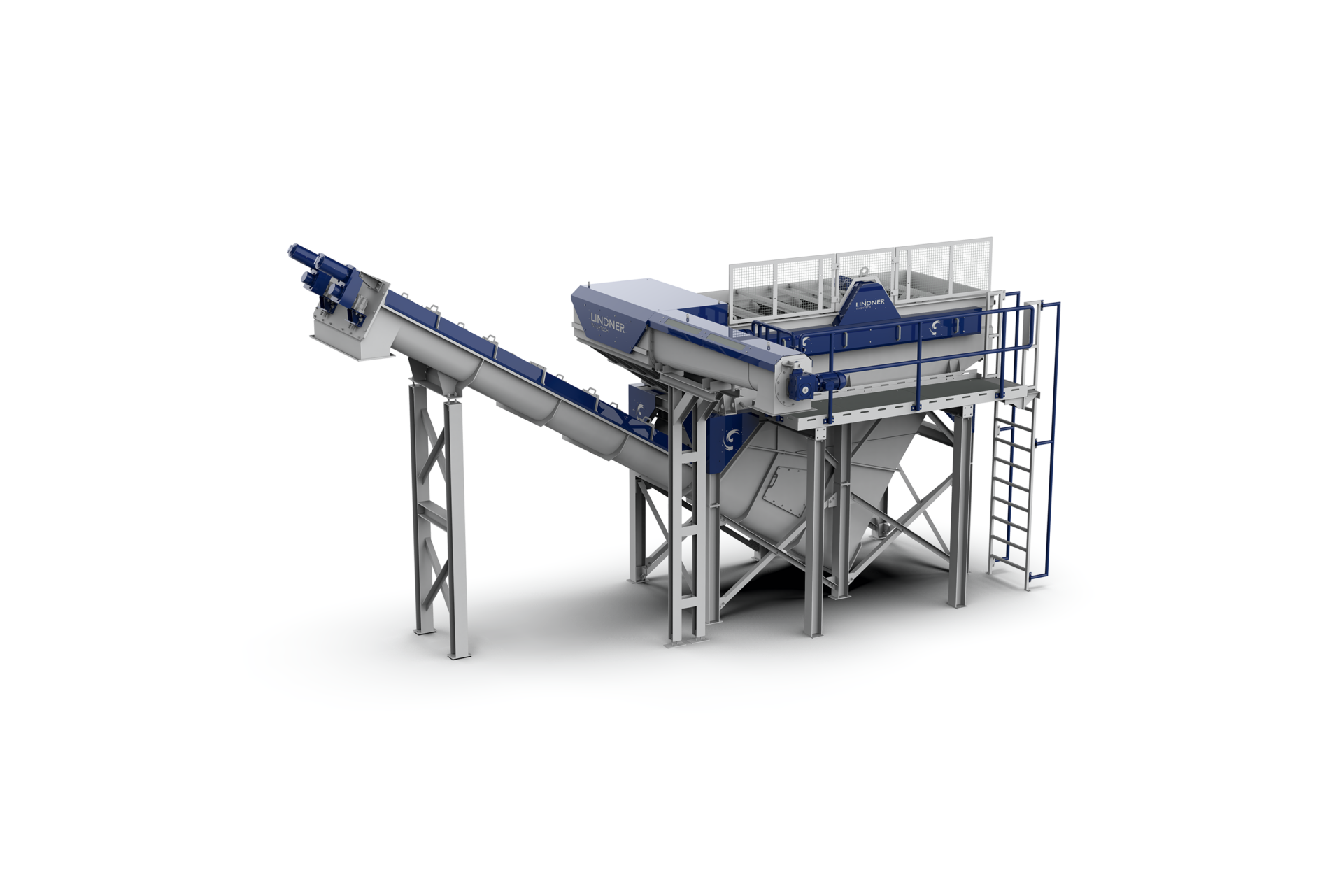

The Lindner Film Examiner is an inline quality optimization unit designed to improve the purity of washed plastic film fractions. Installed after the washing and drying stages, it performs an additional cleaning and separation step to remove remaining light contaminants and fine impurities that conventional washing systems may not fully eliminate.

By enhancing material cleanliness directly within the process flow, the Film Examiner supports the production of higher-quality recyclates suitable for more demanding downstream applications.

Key Features

- Additional mechanical separation stage, targeting residual light particles and contaminants.

- Inline installation capability, allowing seamless integration into existing washing lines.

- Optimized for film fractions, particularly PE and PP films.

- Robust industrial design, ensuring reliable operation in continuous processing environments.

- Low maintenance requirements, with durable components for long service life.

Operational Advantages

- Improved final material purity, increasing the value of the recycled output.

- Higher process yield, as more usable material is recovered.

- Enhanced stability of downstream processes, including extrusion and compounding.

- Cost-effective line upgrade, providing quality improvements without major plant modifications.

Why Film Examiner is Strategic in Plastic Recycling Lines

The Film Examiner acts as a final quality safeguard in plastic washing systems. By removing fine residual contaminants that can affect material performance, it helps achieve higher recyclate standards and more consistent processing results. This makes it a key component for recycling operations targeting premium-quality output and improved market competitiveness.