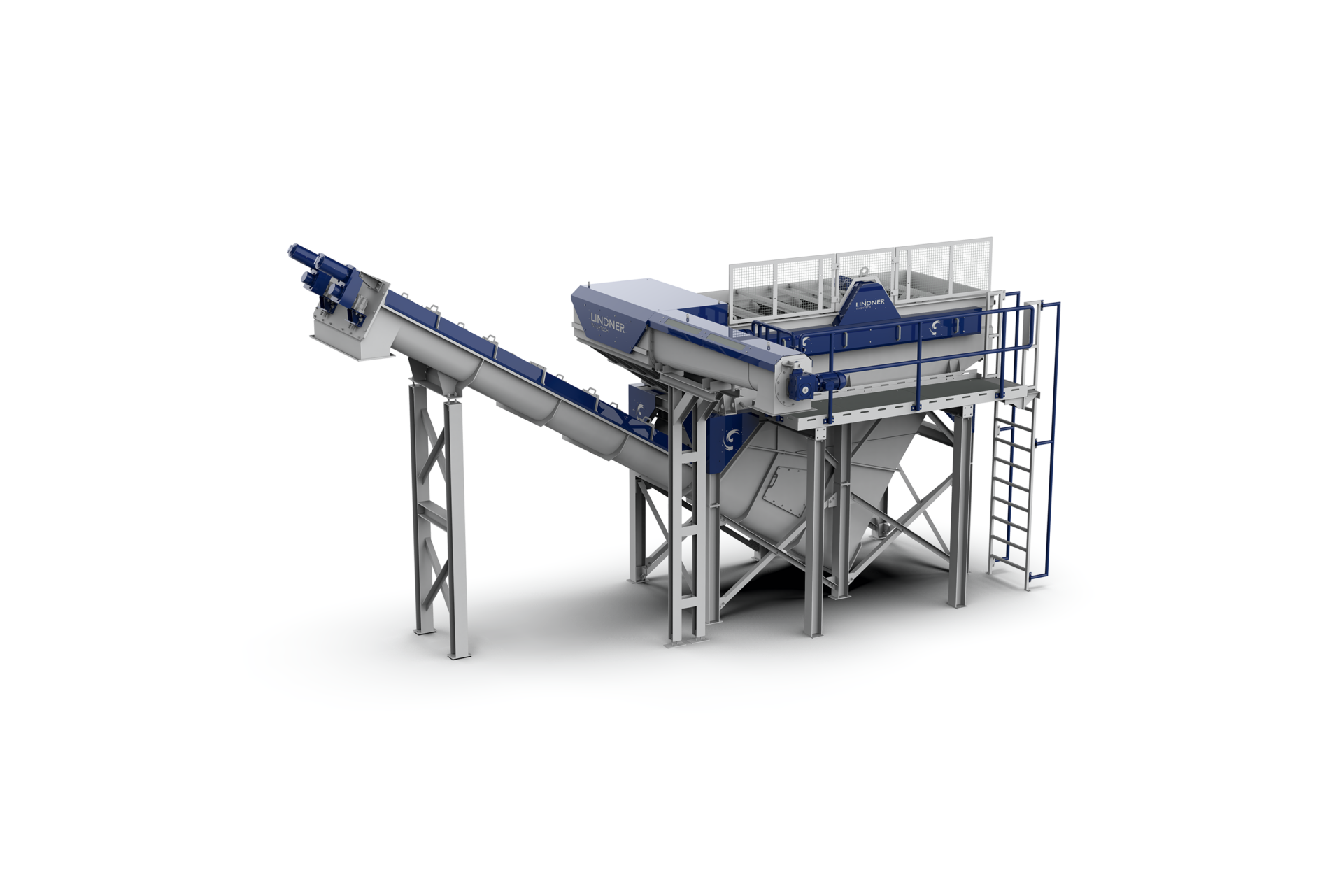

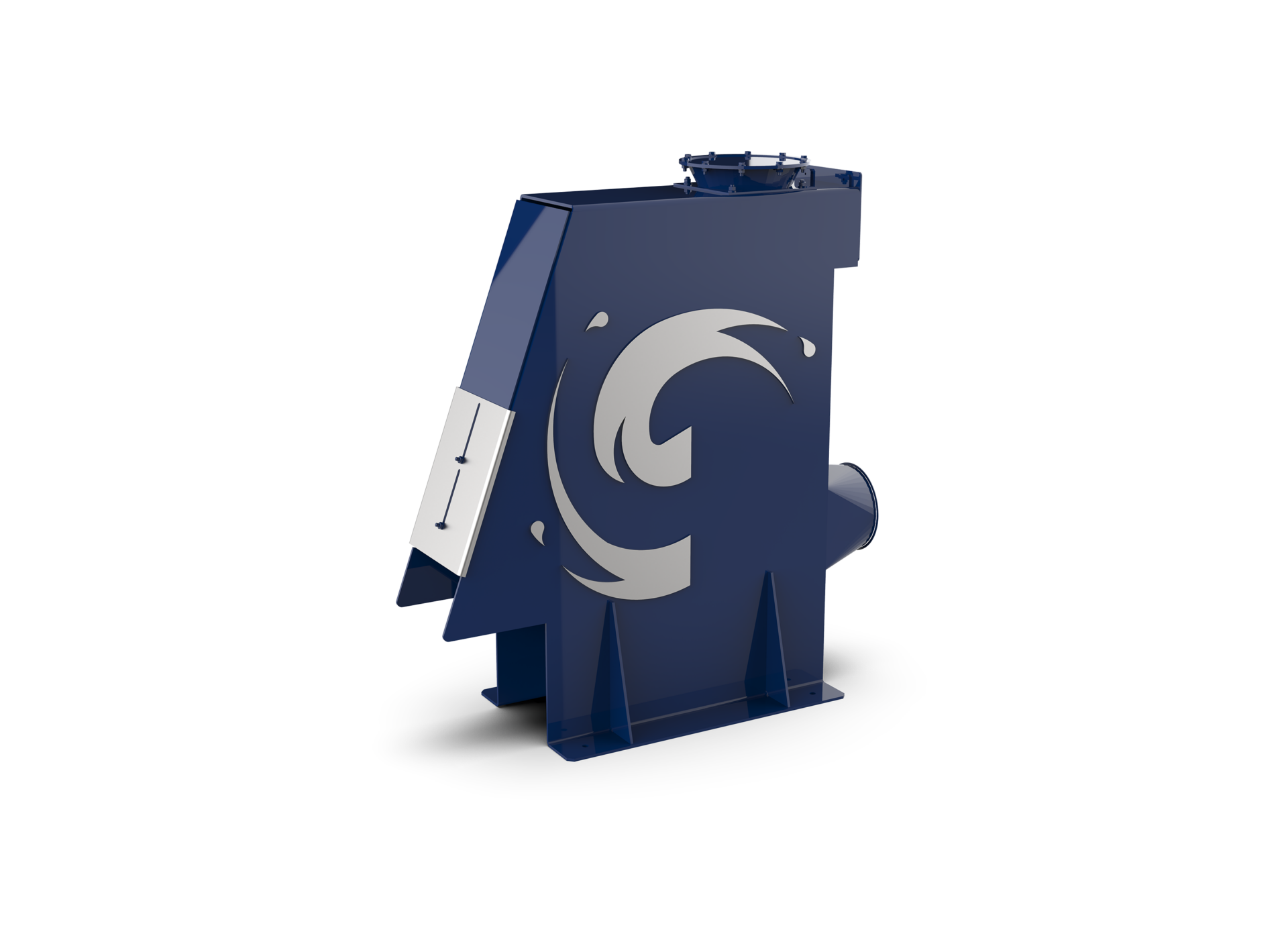

Controlled Dosing and Mixing System

The Lindner Vario Dosing & Mixing Solo is a system designed for the precise dosing and controlled mixing of additives and process agents within plastic washing lines. It plays a key role in optimizing the chemical and physical process parameters, ensuring stable and repeatable operating conditions throughout the treatment stages.

Through accurate flow and proportion management, the system enhances the effectiveness of washing, separation and thermal treatment processes.

Key Features

- High-precision dosing system, enabling controlled introduction of chemicals and process additives.

- Integrated mixing unit, ensuring homogeneous distribution within the process circuit.

- Continuous monitoring of operating parameters, supporting stable and repeatable performance.

- Compact and modular design, allowing easy integration into existing lines.

- Industrial-grade construction, resistant to chemically aggressive environments and designed for continuous operation.

Operational Advantages

- Optimized washing efficiency, thanks to accurate dosing of process agents.

- Reduced chemical consumption, preventing overdosing and minimizing waste.

- Improved process stability, ensuring consistent material quality.

- Simple integration, suitable for both new installations and retrofit applications.

Why Vario Dosing & Mixing Solo is Strategic in Plastic Washing LinesThe Vario Dosing & Mixing Solo ensures precise control of chemical process conditions, a critical factor in achieving high and consistent washing performance. Proper dosing directly impacts contaminant removal, recyclate quality and overall plant efficiency, while also reducing operating costs and environmental impact.